Woodworker's Journal 2004 Spring, страница 57

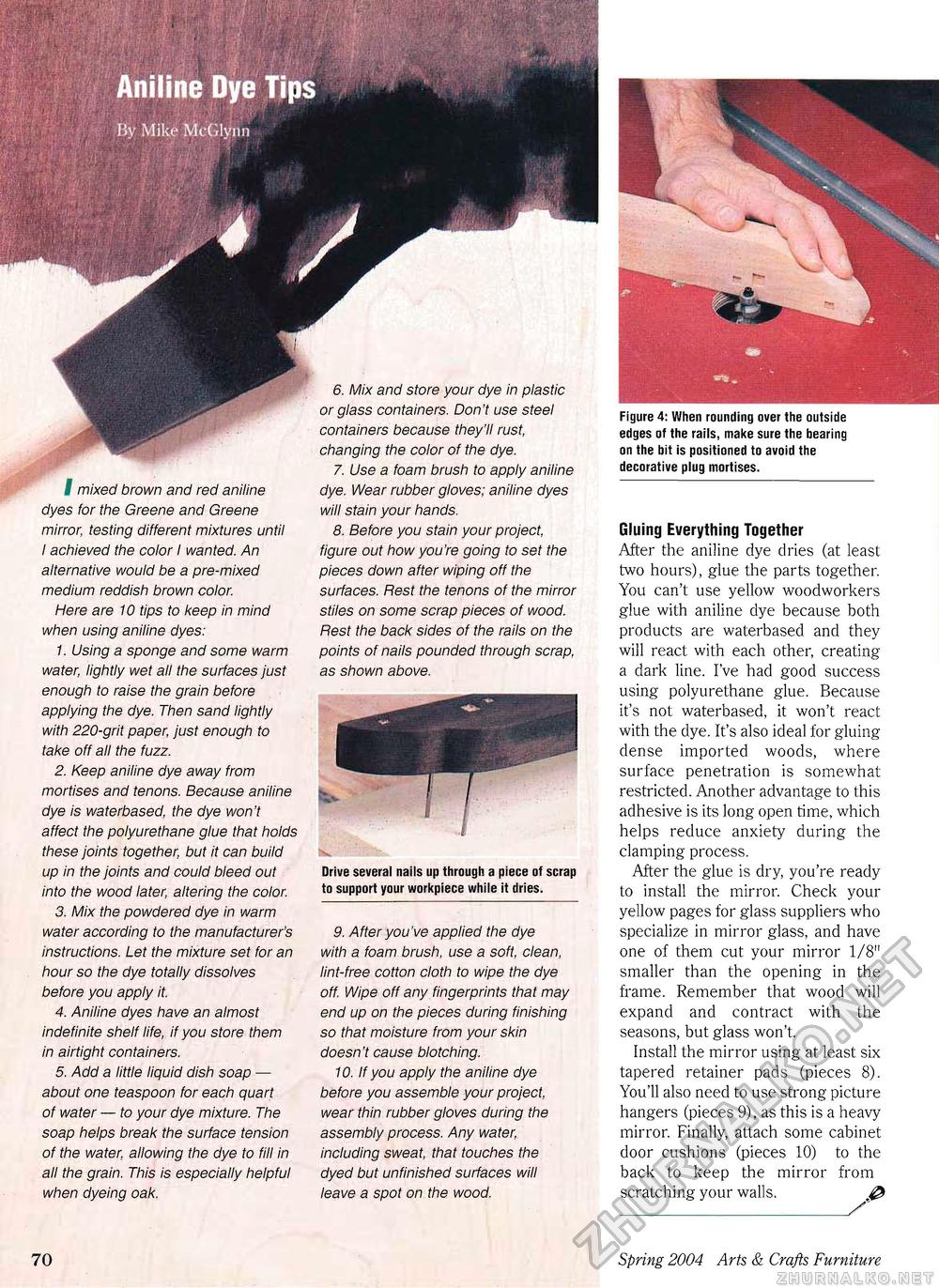

Aniline Dye Tips By Mike McGlyim I mixed brown and red aniline dyes for the Greene and Greene mirror, testing different mixtures until I achieved the color I wanted. An alternative would be a pre-mixed medium reddish brown color. Here are 10 tips to keep in mind when using aniline dyes: 1. Using a sponge and some warm water, lightly wet all the surfaces just enough to raise the grain before applying the dye. Then sand lightly with 220-grit paper, just enough to take off all the fuzz. 2. Keep aniline dye away from mortises and tenons. Because aniline dye is waferbased, the dye won't affect the polyurethane glue that holds these joints together, but it can build up in the joints and could bleed out into the wood later, altering the color. 3. Mix the powdered dye in warm water according to the manufacturer's instructions. Let the mixture set for an hour so the dye totally dissolves before you apply it. 4. Aniline dyes have an almost indefinite shelf life, if you store them in airtight containers. 5. Add a little liquid dish soap — about one teaspoon for each quart of water — to your dye mixture. The soap helps break the surface tension of the water, allowing the dye to fill in all the grain. This is especially helpful when dyeing oak. 6. Mix and store your dye in plastic or glass containers. Don't use steel containers because they'll rust, changing the color of the dye. 7. Use a foam brush to apply aniline dye. Wear rubber gloves; aniline dyes will stain your hands. 8. Before you stain your project, figure out how you're going to set the pieces down after wiping off the surfaces. Rest the tenons of the mirror stiles on some scrap pieces of wood. Rest the back sides of the rails on the points of nails pounded through scrap, as shown above. Figure 4: When rounding over the outside edges of the rails, make sure the bearing on the bit is positioned to avoid the decorative plug mortises. tk. Drive several nails up through a piece of scrap to support your workpiece while it dries. 9. After you've applied the dye with a foam brush, use a soft, clean, lint-free cotton cloth to wipe the dye off. Wipe off any fingerprints that may end up on the pieces during finishing so that moisture from your skin doesn't cause blotching. 10. If you apply the aniline dye before you assemble your project, wear thin rubber gloves during the assembly process. Any water, including sweat, that touches the dyed but unfinished surfaces will leave a spot on the wood. Gluing Everything Together After the aniline dye dries (at least two hours), glue the parts together. You can't use yellow woodworkers glue with aniline dye because both products are waterbased and they will react with each other, creating a dark line. I've had good success using polyurethane glue. Because it's not waterbased, it won't react with the dye. It's also ideal for gluing dense imported woods, where surface penetration is somewhat restricted. Another advantage to this adhesive is its long open time, which helps reduce anxiety during the clamping process. After the glue is dry, you're ready to install the mirror. Check your yellow pages for glass suppliers who specialize in mirror glass, and have one of them cut your mirror 1/8" smaller than the opening in the frame. Remember that wood will expand and contract with the seasons, but glass won't. Install the mirror using at least six tapered retainer pads (pieces 8). You'll also need to use strong picture hangers (pieces 9), as this is a heavy mirror. Finally, attach some cabinet door cushions (pieces 10) to the back to keep the mirror from scratching your walls. ^ 10 Spring 2004 Arts & Crafts Furniture |